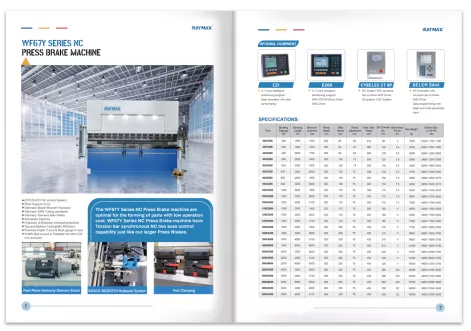

The body adopts four-column frame or composite frame structure, are all steel welded; four angle of eight rectangular guide rails, high precision, good rigidity, and the use of hydraulic pretension. The hydraulic system uses two cartridge integrated valve; the whole system is steady, reliable, long service life, little leakage, little trouble. Electrical system adopts “PLC” programmable controller control, and can be configured according to user requirements proportional pressure, stroke digital display, photoelectric protection device and the mobile station (convenient die change).