- Rapid feeding: The servo hydraulic press has added an independently innovative servo structure design, which has a fast response speed and can quickly apply pressure. Power press pressing speed can reach over 400mm/s, and its pressing effect is better than that of ordinary mechanical punches. Hydraulic power pressmachine can be widely used for pressing hardware or non-metallic products.

- Stretching function: Hydraulic fast press can stretch various materials to form products, such as tableware, kitchenware, motor electrical metal shells, cover bottom plates, and lighting parts. In addition, hydraulic power press adds new touch screen technology, which can directly use non mechanical contact technology to set parameters, making hydraulic press machineeasy to use and highly user-friendly.

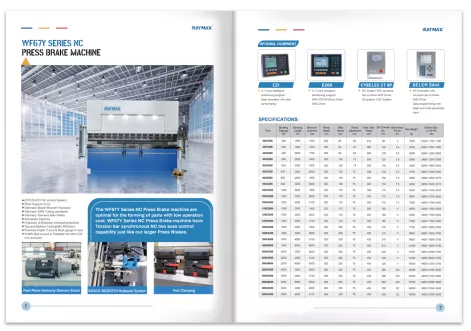

RAYMAX

Y27Y Hydraulic Press Machine

Features

INQUIRE NOW

INQUIRE NOW

PRODUCT DETAILS

Description of Raymax's press machine

Y27Y Hydraulic press machine is a type of punching machine, which is different from mechanical punching and pneumatic punching. Hydraulic power press has the characteristic of being able to use its rated pressure throughout the entire stroke and has the characteristics of hydraulic press equipment. Compared with mechanical punching and pneumatic punching machines, punch press machine has significant advantages in the punching, stretching, and pressing processes of thick plates.

Functions of Raymax's press machine

Stamping & Forming: Hydraulic presses can be used to stamp and form metal, plastic, rubber and other materials through molds to manufacture a variety of parts and products.

Shearing: CNC hydraulic press machine can be used to shear metal sheets, tubes, etc. to obtain the desired shape and size.

Stretching: C frame Hydraulic press realizes the stretching operation of metal materials to deform them into specific shapes.

Imprinting: Hydraulic punch press imprints patterns, words or markings on the surface of the material.