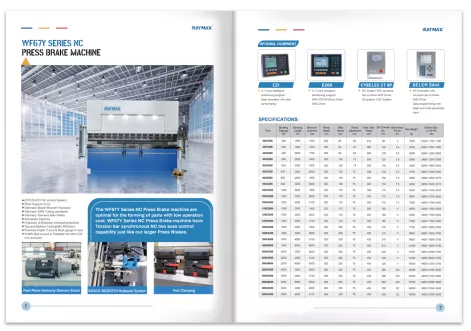

Applicable fields:

This series of hydraulic presses are suitable for various stamping processes such as secondary stretch forming, bending, forming, blanking, and flanging of thin metal sheets, to meet the pressing of multi-planar complex structures, and are especially suitable for the following fields:

Auto parts: body cover, brake pads, fuel tank, chassis, axle housing, bumper;

Household appliances: washing machine parts, rice cooker parts: TV parts, refrigerator parts, etc.;

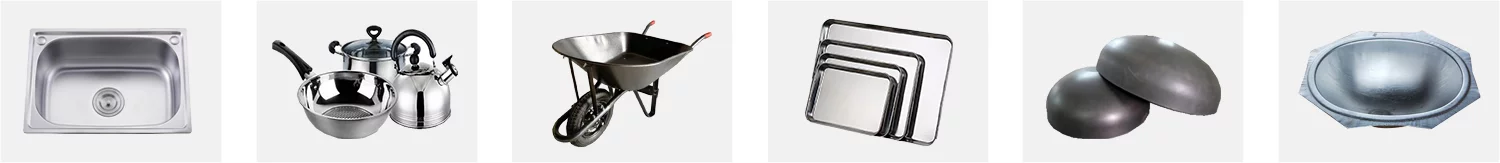

Kitchen appliances: sinks, pots, stainless steel appliances, other containers;

Others: tractors, motorcycles, aerospace, aviation.

INQUIRE NOW

INQUIRE NOW