RAYMAX HYBRID SERVO

-

-

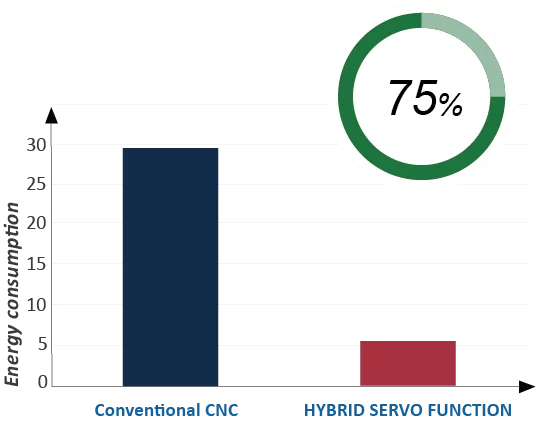

40% Energy Saving

-

Noise Reduction Within 60 db

-

Low Fuel Consumption

-

High Efficiency

-

Good Sealing Performance

-

-

Significant energy saving

one of the advantages of servo drive technology is that the input power of the motor is directly proportional to the size of the load power, the power consumption is large when bending, the power consumption is small when the slider is unloaded, and basically does not consume power when the slider stops. However, the main motor and hydraulic pump of the hydraulic servo bending machine continue to run even if the slider does not work, consuming electricity.

-

Environmental protection and no pollution

servo press brake does not use hydraulic oil, no replacement of hydraulic oil, disassembly and replacement of hydraulic components, there is no replacement, disassembly and replacement process and the system of daily hydraulic oil leakage, there is no waste oil treatment and pollution.

-

Fast slider speed, high productivity

The response speed of the servo motor is faster than that of the hydraulic servo. The hydraulic servo press brake is affected by the environment and the heating of the hydraulic system, and needs to be started for preheating or stopped for heat dissipation; Once there is a malfunction in the hydraulic system, the technical requirements for troubleshooting are high and the time is long. However, the servo press brake has few components and low failure rate, so these problems do not exist at all.

-

High bending precision

the bending speed of the servo press brake is adjustable, which can be set to use more appropriate bending speed for different thicknesses, materials and bending lengths to improve the bending precision and maintain high productivity.

-

Low maintenance and use cost

the hydraulic oil of the hydraulic press brake needs to be replaced regularly; Pumps, valves, and seals are prone to malfunction and damage, and hydraulic systems are prone to contamination. It is difficult to find and eliminate faults. Once the hydraulic system is contaminated, it is difficult to clean the system, and all of these can cause environmental pollution. The transmission system of the servo press brake is simple, with no maintenance cost, and only needs regular lubrication.

RAYMAX HYBRID PLUS

ADVANTAGES

-

Saving

60% electricity savings compared to conventional drives.

-

Efficient

High up to 30%, more efficient (reduced cycle time).

-

Accurate

More accurate positioning, up to 5um

-

Quiet

Quieter of machine operation due to reduced noise

-

Less

Hydraulic oil use is minimal, only 30% compared to conventional ones

-

Easy

Easier to build, easier to maintain and lower failure rate of the machine.

SYSTEM FEATURES

Minimize the overflow loss.

Infinitely adjustable speed can be realized. Adjustment range can from 0 to maximum. Precise demand oil quantity dispensing is optimized by the speed of dynamic servo motor.

Compared with two-way pump servo control and ordinary directional valve control, double servo pump control has smoother operation, easy and convenient installation, beautiful appearance, reliable performance, simple control and low failure rate.

No idle power, servo motor can be turned off when no flow or pressure is needed.

Compact design, tank assembly and cylinder are connected together by transition block, no piping connection.

Further improves cleanliness. Makes machine building easier.